Esta página web utiliza cookies propias y de terceros para fines funcionales (permitir la navegación web), para optimizar la navegación y personalizarla según tus preferencias así como para mostrarte publicidad en base a tu perfil de navegación (p.e páginas visitadas). Para más información acceda a la Política de Cookies.

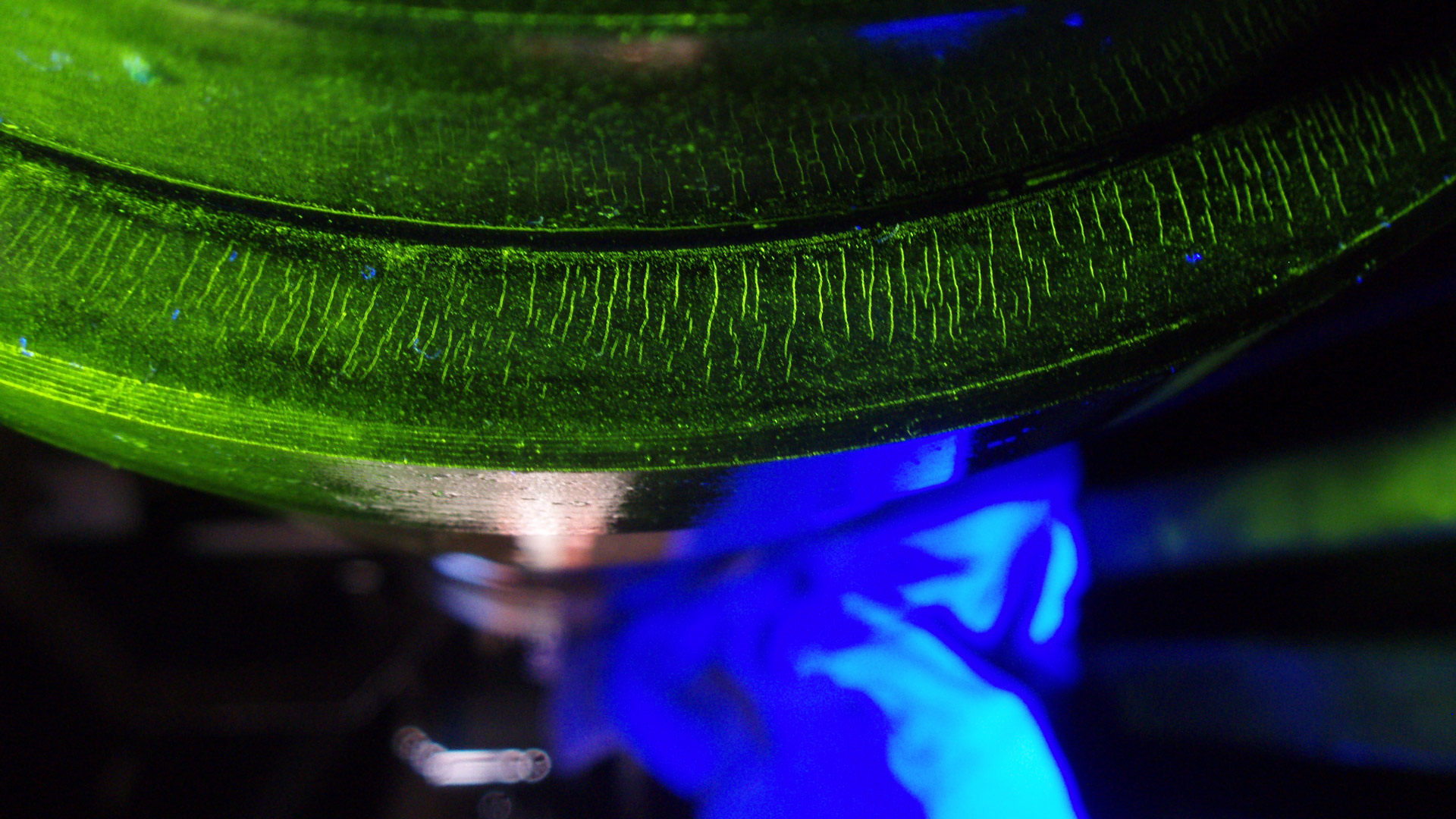

Liquid penetrant testing (PT)

Penetrating liquids are one of the most widespread, simple and effective non-destructive tests. These liquids help detect defects and imperfections on the surface of the components on in-service inspections and fabrication processes that are not perceptible in a visual inspection. This technique can be applied to any surface of a non-porous material. The test is performed applying a penetrant liquid on the surface of the material, which will penetrate the imperfections in the piece. The excess liquid on the surface is removed afterwards so that it only remains on the imperfections, showing their exact location on the piece.

In OCA Global we use several liquid penetrant testing methods to detect internal defects or cracks from the surface. In order to do so, liquids with red or fluorescent ink (process carried out in a black light environment to ensure the detection of the finest fatigue cracks) are used, as well as other types of liquids and dry developers.

Within the field of application of penetrating liquids, whose objective is the detection of discontinuities such as cracks, plies, pores, etc., in the surface of metallic materials welded joints, or in the surface of non-metallic materials, always with the condition that they are inert to the test products and that they are not excessively porous.

Applicable regulations

ASME CODE

Test performance

Section V

Indication assessment

Section VII Division 1

STANDARDS

Test performance

UNE 141612

UNE-EN 571-1

Indication assessment

UNE-EN 571-1

Indication assessment

UNE-EN 1289

UNE-EN 1289/1M

UNE-EN 1289/A2

UNE-EN-ISO 5817