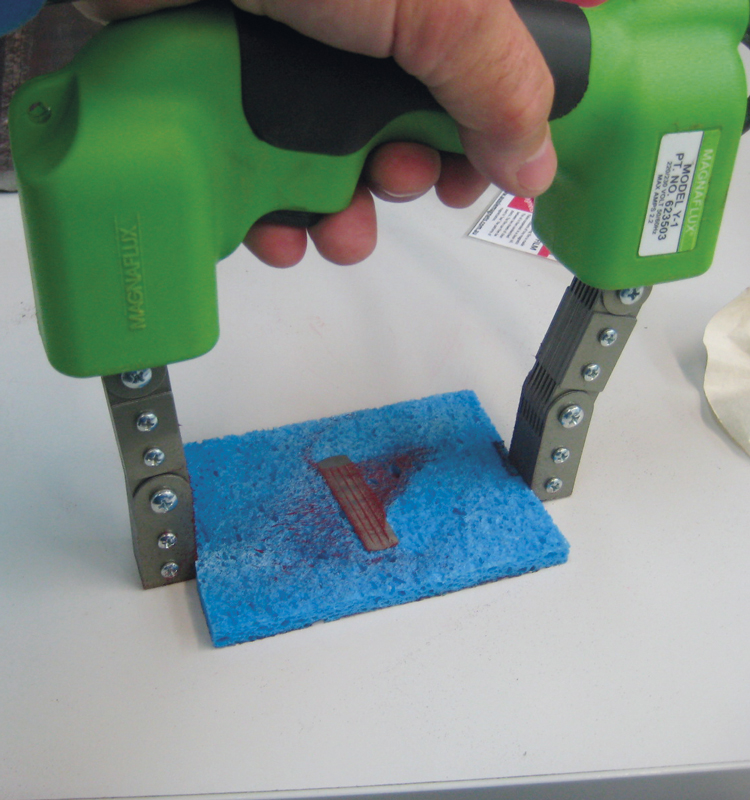

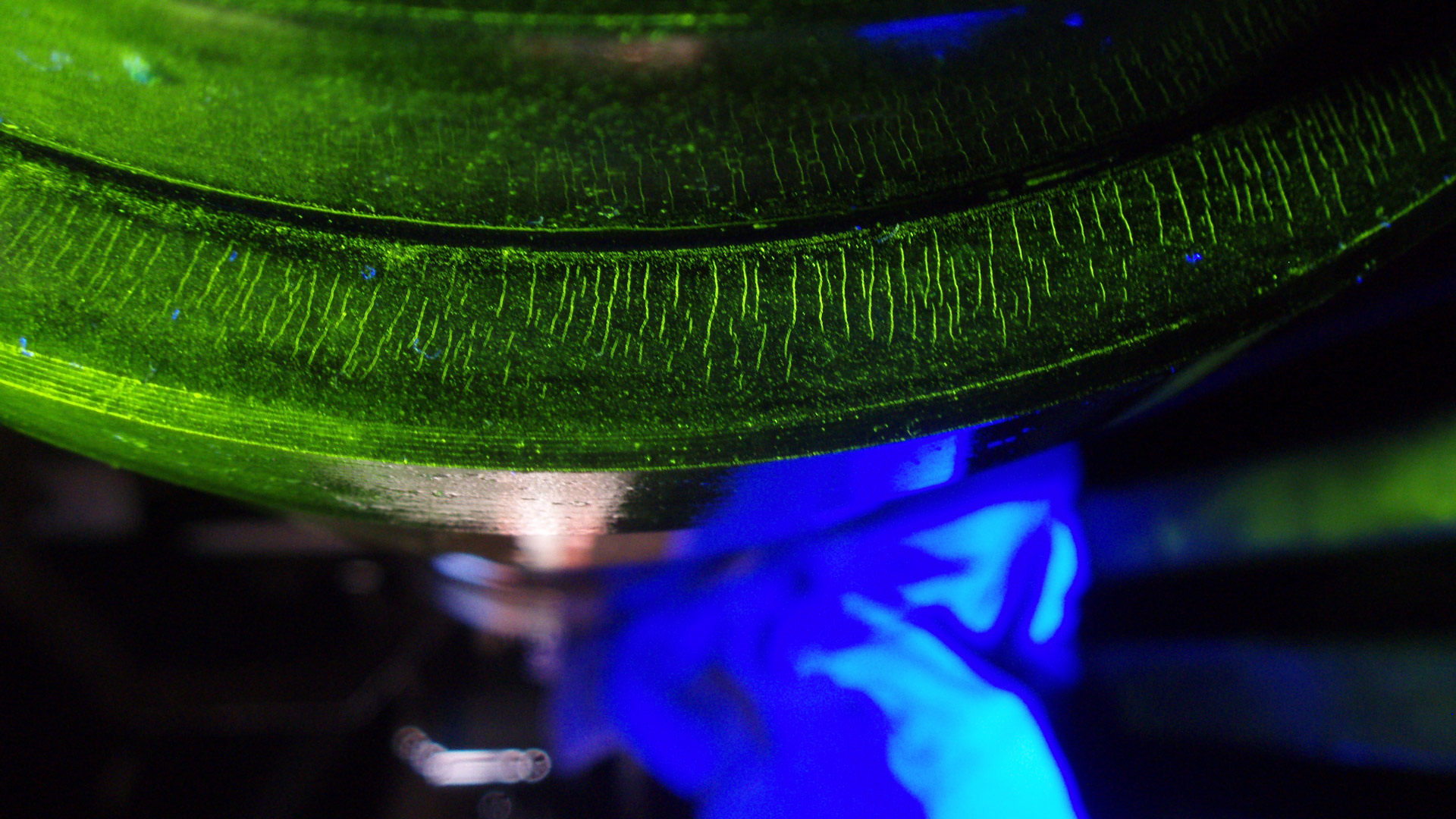

Magnetic particle inspection (MT)

The purpose of these inspections is to establish the operating method and the acceptance criteria for magnetic particle tests in welds to detect defects or discontinuities in the surface or subsurface – such as fissures, folds, blowholes or imperfections.

The highest sensitivity when performing this test is obtained in surface discontinuities and it decreases rapidly as the depth of the discontinuity increases.

This method is applicable only in ferromagnetic materials, using the technique of electromagnetic yokes and using visible colour or fluorescent magnetic particles.

This test can be performed on components with certain coatings and on samples of large or small size, and the results are obtained immediately.

Applicable regulations

ASME CODE

Test performance

Section V

Indication assessment

Section VIII Division 1

STANDARDS

Test performance

UNE 1290

UNE-EN 1290/1M

Indication assessment

UNE-EN 1291

UNE-EN 1290/1M

UNE-EN 1291/A2

UNE-EN-ISO 5817