Esta página web utiliza cookies propias y de terceros para fines funcionales (permitir la navegación web), para optimizar la navegación y personalizarla según tus preferencias así como para mostrarte publicidad en base a tu perfil de navegación (p.e páginas visitadas). Para más información acceda a la Política de Cookies.

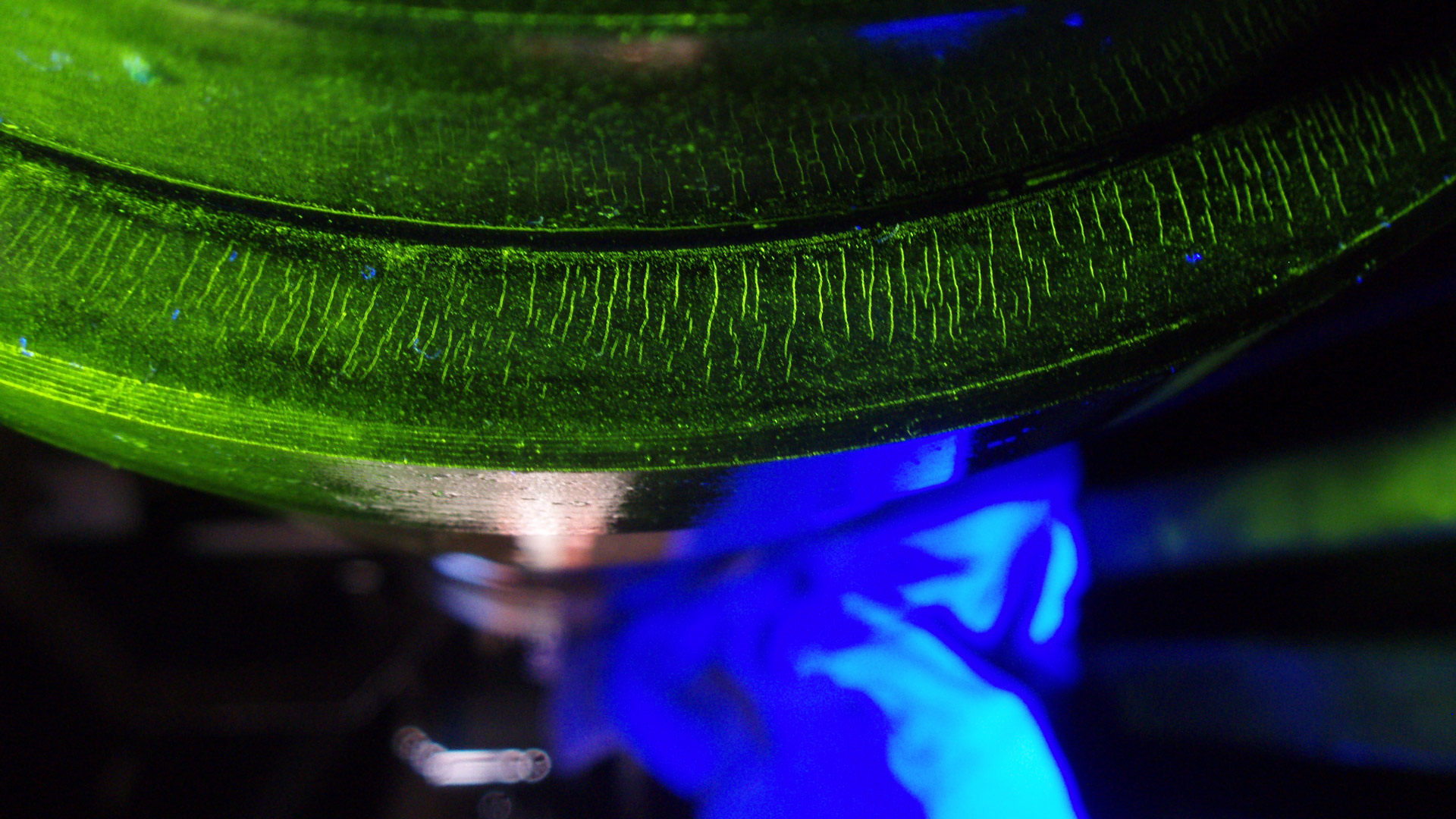

Ultrasonic testing (UT)

Ultrasounds are sounds produced by mechanical vibrations that have a frequency above audible level. Like sounds, ultrasounds travel through a medium with a defined speed and in the form waves, but, unlike electromagnetic waves, the sound wave is a mechanical disturbance of the medium through which energy is transported.

Ultrasonic tests use high frequency sound energy to examine the quality and integrity of the components and welds, allowing to find internal discontinuities in the materials, defects in a piece, welding or metal sheet as well as, for example, to determine its thickness.

Ultrasonic testing can be especially useful when facing access, temperature, coating or type of material and components problems. Our team is able to perform this type of inspection quickly and accurately. Some of the specific areas where we can apply this method are: pipes and ducts, pressure vessels, power plants, storage tanks, and railways.

The welded joints ultrasonic testing method intended for the construction of metallic steel structures subjected to static loads (buildings) or dynamic loads (bridges), is applicable to the ultrasonic test of the seam annealing and thermally affected zone (ZAT) of chamfer welds with a thickness of 8 to 200 mm, both included.

If the thickness is lower than 8 mm or higher than 200 mm, the test may be carried out in accordance with Annex S of AWS D1.1, upon approval of the contractor or engineering company.

Applicable regulations

ASME CODE

Test performance

Section V

STANDARDS

Test performance

UNE 1290

UNE-EN 1290/1M

Indication assessment

UNE-EN 1291

UNE-EN 1290/1M

UNE-EN 1291/A2

UNE-EN-ISO 5817