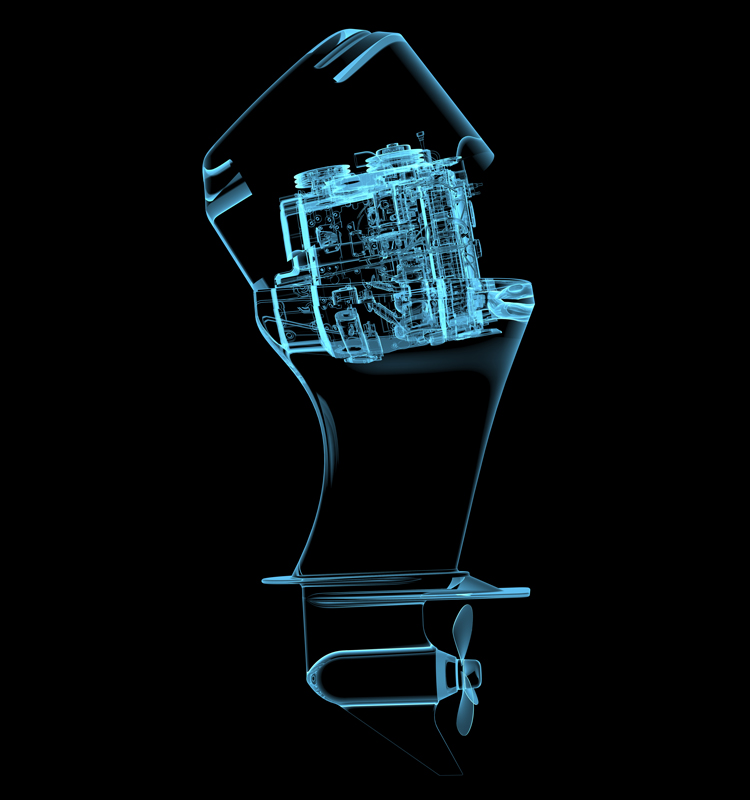

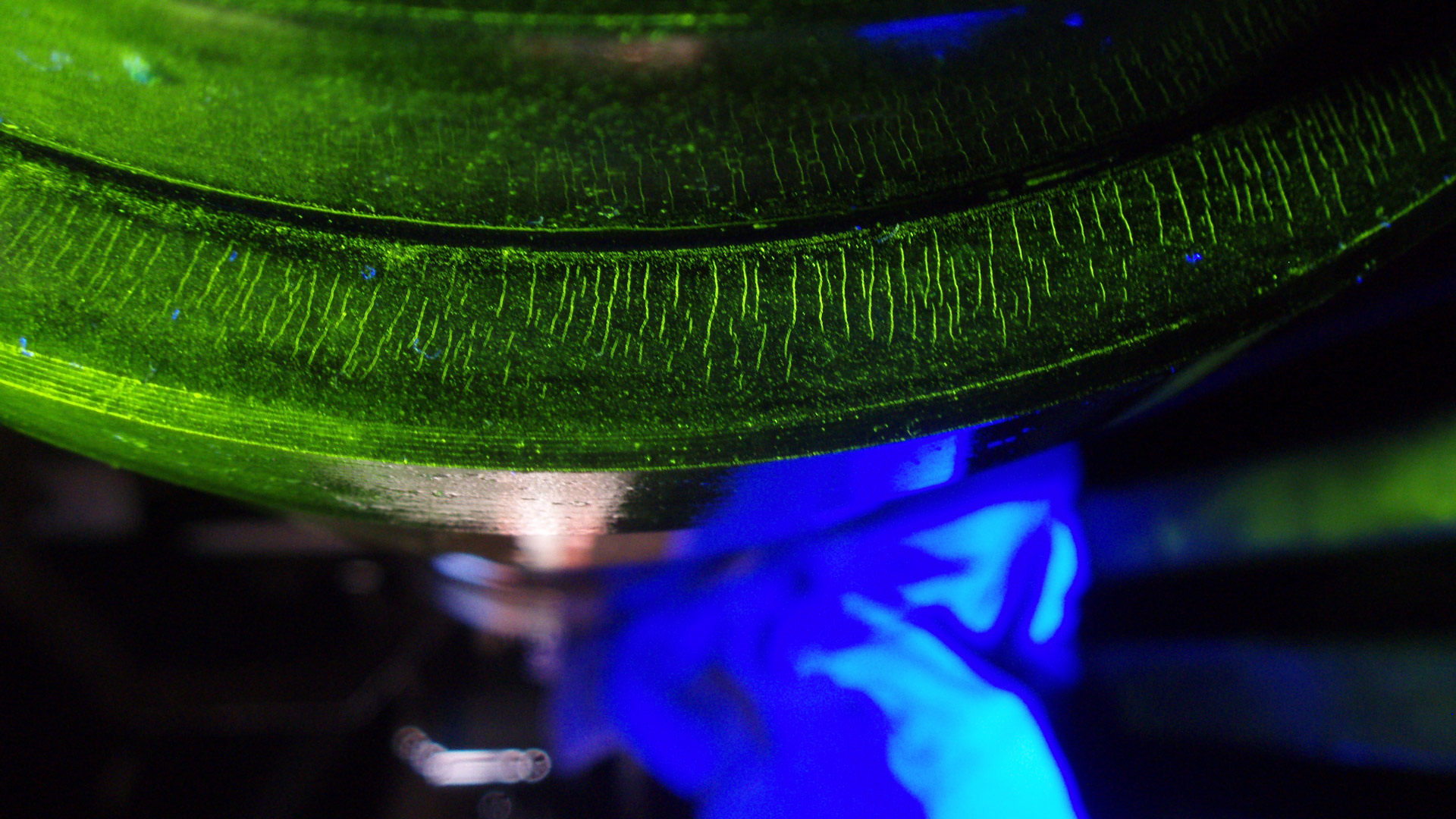

X-Ray and radiographic testing

These inspections are established with the operating method and the acceptance criteria to test welded steel structures using X-ray or radiographs.

This method is applicable to the radiographic testing of chamfered welded joints, with complete penetration in sheets and structural and tubular profiles using scintigraphic sources.

We can also find inspections of welded joints carried out using the radiographic method, which is intended to describe the test method and the evaluation criteria to test welds in oil storage tanks through radiographic tests. The radiographic test is required for welding in:

- The body (ferrules) of the tank.

- Annual plates of the bottom of the tank.

- Tank manhole.

The plates will be considered of the same thickness if the difference of their nominal thickness does not exceed 3 mm.

Radiographic tests are a non-destructive testing method used to test and inspect different materials without causing any damage or alteration in the piece and its materials. In these tests, the radiation of X-ray or gamma equipment is absorbed by the material, allowing to observe the interior of objects and assessing whether there is corrosion, erosion, defects or foreign objects that endanger its operation and use.

Applicable regulations

ASME CODE

Test performance

Section V

STANDARDS

Test performance

UNE 1290

UNE-EN 1290/1M

Indication assessment

UNE-EN 1291

UNE-EN 1290/1M

UNE-EN 1291/A2

UNE-EN-ISO 5817